Liquid Disinfectant

| Product name | TG Ballastcleaner® |

|---|---|

| Main component | NaClO (sodium hypochlorite) |

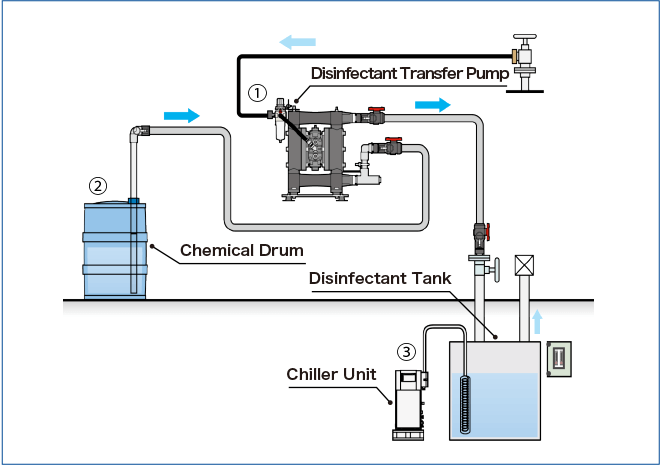

Sodium hypochlorite needs to be stored at 20°C or lower. When the chemical drum containing the chemical is delivered onboard, be sure to fill the disinfectant tank using the disinfectant transfer pump as soon as possible.

Supply and Storage

How To

- Connect each hose side of Disinfectant Transfer Pump supplied by JFE with the chemical drum and to the supply port on the upper deck leading to Disinfectant Storage Tank.

- The transferring process should take approximately 5 minutes per drum (200L). Please repeat this process the required amount of times until the Disinfectant Storage Tank is filled.

- Liquid disinfectant is stored in the Storage Tank at a temperature of 10 degrees Celsius.

Neutralizer

| Recommended product by JFE | TG EG (TG Environmentalguard®) |

|---|---|

| Main component | Na2SO3 (sodium sulfite) |

Sodium sulfite is delivered as a powder. It should be dissolved with freshwater in the Neutralizer Dissolution Unit before being injected to the ballast water.

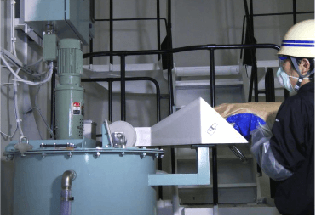

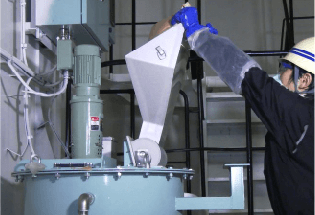

How To

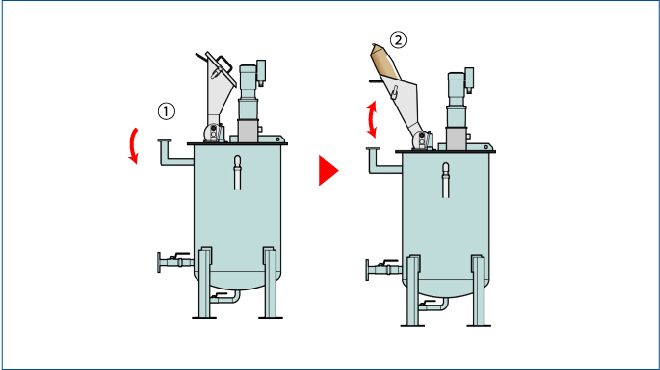

- Tilt the supply port of the Neutralizer Dissolution Unit 90 degrees towards you. Put a 25kg bag on the supply port, then open it inside the supply port.

- Lift up the supply port to pour in the neutralizer powder and dissolve it with freshwater in the Neutralizer Dissolution Unit. Repeat this process the necessary number of times to make the desired amount of neutralizer solution.

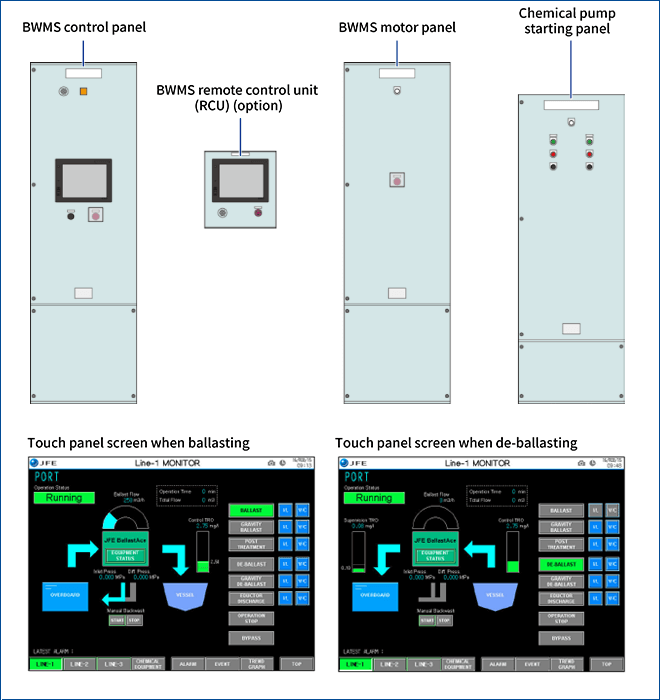

BWMS

The BWMS control panel supervises and controls the BWMS with signals (A/I, A/O, D/I, D/O) corresponding to each device.

System operation and individual component operation can be performed on the touch panel. It also has a logging function, and can also show the trend graph.

The BWMS remote control unit (RCU) can be installed as an option, enabling operations to be performed from a remote location, such as the ships’ office. Unlike the BWMS control panel, the RCU cannot perform individual component operation or various parameter settings.